TXIB/OE300(Plasticizing AREA) is used for emulsion paint, with excellent hydrolysis stability, low freezing point of dodecanol ester, and no special treatment is required in winter.

Shipping Information

Martime or Air Shipping ,to South Korea, Argentina US etc.

MOQ:1FCL

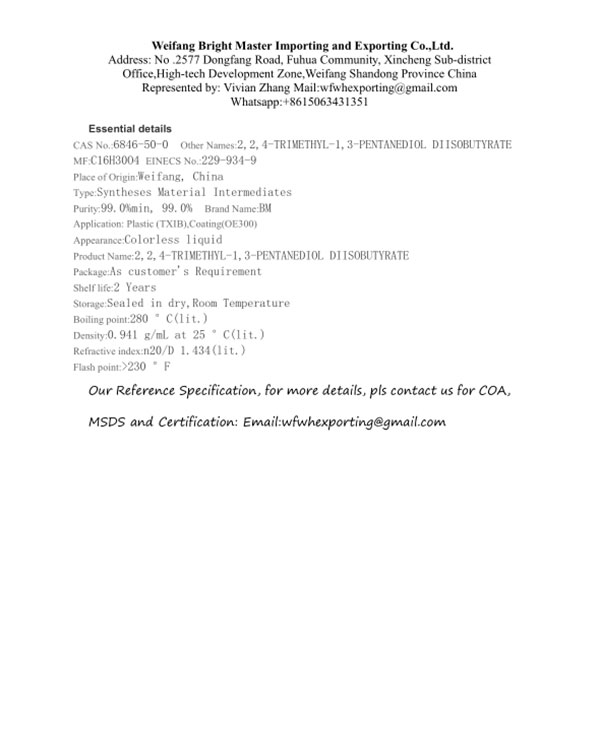

Specifications

Usage method

1. For emulsion paint, the addition amount of dodecanol ester is mainly based on the hardness of lotion polymer. The harder lotion (high Tg value) needs more addition amount than the soft lotion (low Tg value) to achieve the same film forming effect. In addition, different formulations of the same lotion (different PVC) also require different amounts of ester alcohol.

2. In general, the addition amount of dodecanol ester is considered as 3-10% of the solid content of lotion. Higher addition amount can get better effect. When the solid content of lotion is not more than 12%, the stability of lotion will not be affected.

3. The operation of using ester alcohol in the production of lotion paint is very simple. In principle, it can be directly stirred and added at any stage of production. If gel phenomenon occurs in the process of adding, it can be premixed with ester alcohol with water and surfactant that should be added in the production of latex paint, and then its mixed solution can be added to the lotion.

4. Dodecanol ester can only be added in two times to give full play to its role.

Key Features

Eastman plasticizer OE300 environmental viscosity reducer CAS 6846-50-0